Surface Coatings & Finishes

Comprehensive Solutions at MDP Precision

Surface coatings and finishes are not just about aesthetics.

They are a critical element ensuring durability, functionality, and safety of industrial components. Unprotected metal surfaces are exposed to corrosion, mechanical wear, and degradation, leading to failures, downtime, and costly replacements.

Why are protective coatings essential in industrial production?

Surface coatings and finishes are not just cosmetic – they are a critical element ensuring durability, functionality, and safety of industrial components. Unprotected metal surfaces are exposed to corrosion, mechanical wear, and degradation, leading to failures, downtime, and costly replacements.

Key functions of coatings:

- Corrosion protection – protection against moisture, salts, and chemicals.

- Mechanical resistance – resistance to abrasion and impact.

- Hygienic – smooth surfaces for pharma and food industries (GMP, HACCP).

- Aesthetic – appearance aligned with client branding

We offer:

Galvanic zinc plating, powder coating, mechanical polishing of stainless steel, passivation, and surface preparation.

Lead time 7-14 days | Quote within 24h.

Types of Coatings at MDP Precision

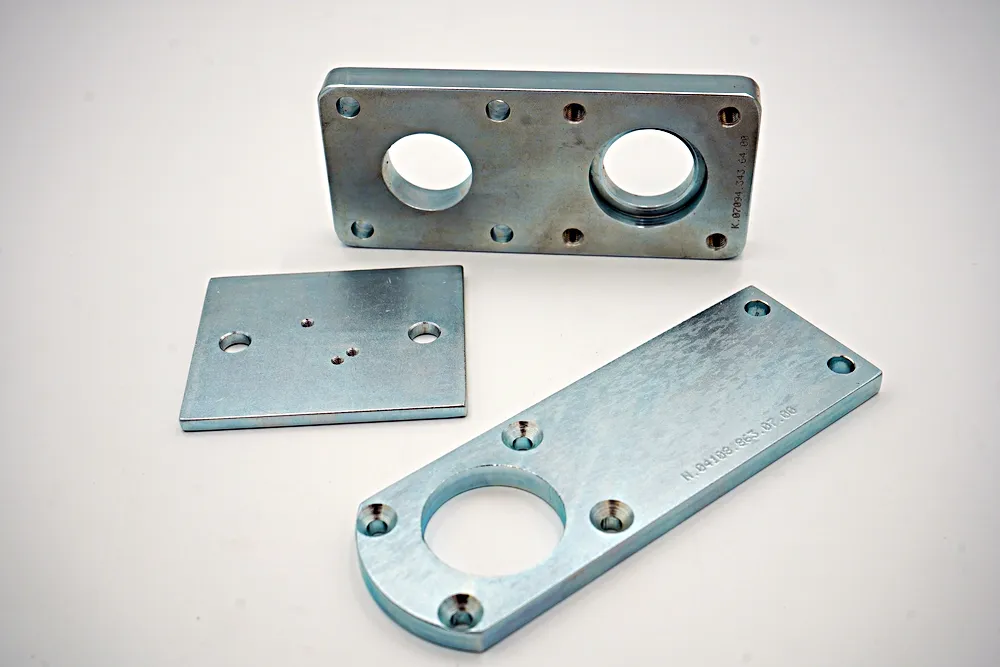

Galvanic Zinc Plating

Corrosion Protection

Electrochemical application of zinc layer onto steel. Zinc protects as a barrier and sacrificial anode – even when the coating is damaged.

Parameters:

- Thickness: 5-25 μm (adjusted to working conditions)

- Passivation: blue-gray finish, enhanced resistance

- Uniform coverage of holes, recesses, and edges

- Control: magnetic measurement in accordance with DIN/ISO

Applications:

Fasteners, brackets, housings, automotive components, industrial installations.

Powder Coating

Durability and Aesthetics

Application of polymer powder thermally cured at 180-200°C. High mechanical, chemical, and atmospheric resistance.

Parameters:

- Thickness: 60-120 μm

- Preparation: degreasing, sandblasting, phosphating

- Wide range of colors and finishes (matte, gloss)

- Testing: adhesion by cross-cut method (ISO 2409)

Benefit:

Completion 3-5 days faster than outsourcing to external paint shops.

Applications:

Machine housings, welded structures, panels, equipment covers.

Mechanical Polishing

Mirror Finish

Removal of surface irregularities using abrasives of decreasing granulation. We achieve Ra < 0.8 μm (mirror finish) for pharmaceutical and food industries.

Parameters:

- Roughness: Ra < 0.8 μm (GMP, HACCP)

- Material: stainless steel 304, 316L, 316Ti

- Smooth surface = no bacterial adhesion, easy cleaning

- Also available: satin finishing (matte), sandblasting (texture)

Applications:

Pharmaceutical tanks, food-grade piping, medical housings, cosmetic components.

Stainless Steel Passivation

Chemical removal of free iron and formation of chromium oxide layer. Restores natural corrosion-resistant properties after machining/welding.

Process:

Nitric or citric acid (depending on steel grade).

Applications:

Chemical, marine, pharmaceutical, food industries; chemically aggressive environments.

CNC machining, welding, and coatings from three suppliers waste time and money. MDP Precision handles everything in-house – eliminating delays, logistics issues, and additional costs. ISO 3834-2 certification and the trust of clients like ThyssenKrupp, KUKA, and Polpharma guarantee quality at every stage.

Why MDP Precision

High-quality welds are one of the greatest advantages of TIG welding. This technique ensures smooth, clean, and aesthetic connections, which is crucial in many industries such as aviation, chemical industry, and sheet metal work.

Elimination of Logistics

One facility = zero transport between suppliers. Component after CNC → welding → coating without leaving the hall.

Lead time reduction: up to 40% vs. multi-supplier model.

Full Quality Control

ISO 3834-2 covers the entire process: machining → welding → coatings → inspection.

Documentation: one comprehensive package instead of collecting certificates from three companies.

Single Point of Contact

One inquiry = comprehensive quote. MDP Precision engineer advises on machining, welding, and coating technologies.

Time savings: zero coordination with multiple suppliers.

Fast Turnaround

External coating facilities: 7-14 day queue. MDP Precision: 24-48h from machining to coating.

Urgent projects: completion in 3-5 days from order.

Yes. Domestic and international courier services (Poland, Germany, UK, Scandinavia). Protected against damage – polished elements in protective sleeves, welded structures in custom-fit packaging.

Yes. Prototypes and production runs. No minimum quantity – each order is treated individually.

Min: several cm (screws, bushings). Max: zinc plating up to 1000x500x300mm, powder coating up to 2000x1000x1000mm, polishing virtually unlimited.

Yes. Technical parameters (thickness, temperature, time) + inspection protocol + measurement results. For projects requiring material certification: full traceability.

Zinc plating: structural steel, low-alloy steel. Powder coating: steel, aluminum, cast iron. Polishing: stainless steel 304, 316L, 316Ti. Passivation: all grades of stainless steel.

Coatings: 2-3 days from machining/welding completion. Complete service (machining + coatings): 7-14 days. Express mode: 3-5 days.

Quoted separately. However, comprehensive execution (machining + welding + coatings) is often more cost-effective than coordinating three separate suppliers due to elimination of intermediary margins.

We offer a full range of coatings: galvanic zinc plating, powder coating, mechanical polishing, stainless steel passivation, and surface preparation (sandblasting, shot blasting, satin finishing). All processes are performed in-house at our facility in Pruszcz Gdański.