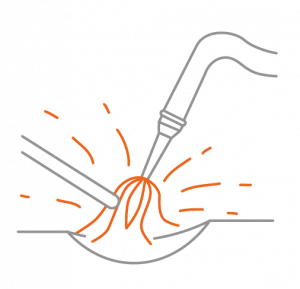

Our company specializes in professional gas welding, offering solutions tailored to the individual needs of our clients.

With years of experience and advanced equipment, we deliver durable and precise metal joints that meet the highest quality standards.

Applications of gas welding

AUTOMOTIVE INDUSTRY

Repair and production of vehicle components such as exhaust systems, body panels, or suspension parts. Joining thin metal sheets with precise heat control to prevent deformation.

MANUFACTURING INDUSTRY

Production of metal furniture, railings, and decorative metal elements. Creating durable and aesthetically pleasing joints for high-quality products.

CONSTRUCTION

Welding steel structures, pipes, and metal components in buildings and infrastructure. Ideal for on-site repairs and installations due to portable equipment.

AEROSPACE INDUSTRY

Precise welding and repair of aircraft components and critical parts with high accuracy. Working with strong metal alloys thanks to the high flame temperature.

SHIPBUILDING INDUSTRY

Joining and repairing metal components in ships and port infrastructure. Capable of operating in challenging field conditions due to equipment mobility.

MAINTENANCE AND REPAIRS

Rapid on-site repairs of machinery and equipment in industrial facilities. Extending equipment lifespan through the regeneration of worn parts.

Why choose our gas welding services?

CLIENT TRUST

Our services are highly regarded by clients who value our professionalism and quality workmanship.

MODERN TECHNOLOGIES

We utilize state-of-the-art equipment to ensure the highest quality of our services.

EXPERIENCE

Our team consists of skilled welders with the expertise needed to execute every project with utmost precision.

AVAILABILITY AND FLEXIBILITY

We are ready to undertake projects in various locations and conditions.

Which welding method is right for you?

Key Differences:

- Precision: TIG welding offers the highest weld quality, making it ideal for precise work on thin sheets or unconventional materials.

- Efficiency: MIG 131 and MAG 135 methods are significantly faster than gas welding or TIG, making them more suitable for mass production.

- Cost: Gas welding is the most cost-effective in terms of equipment and operation, while TIG incurs the highest costs.

- Mobility: Gas welding is the most mobile, requiring no electrical power supply.

Summary

- For precision and aesthetic welds, choose TIG.

- For fast industrial production, MIG 131 or MAG 135 are the best options.

- Gas welding is ideal for field repairs and areas without access to electricity.